SWAT Partner Announcement: Peninsula Precision Ag

In order to harness the potential for uptake of precision ag services on the Yorke Peninsula in South Australia, Matt Correll recently founded his business, Peninsula Precision Ag to do just that. Peninsula Precision Ag is a new independent agronomy company and SWAT MAPS service provider, dedicated to helping producers in South Australia utilize premium precision ag services to further their farming operations.

As an independent agronomist, Correll moved into precision agriculture after exploring software, collecting yield maps and creating prescription applications.

“I was trying to find ways of narrowing down the data into high-definition layers, which is how I stumbled on EC mapping and what SWAT MAPS offers,” said Correll. “In terms of business, the SWAT ECOSYSTEM allows me to rapidly expand my company through the thought-out planning and products that are available to me. The ongoing support will be essential to continue to develop and learn about how precision ag can be applied to the local growing region.”

Correll’s clients in Yorke Peninsula mostly grow wheat, barley, lentils and canola. Due to varying soil types, Correll notes that there is great potential for producers in that region to utilize SWAT MAPS to make more informed decisions for their operations.

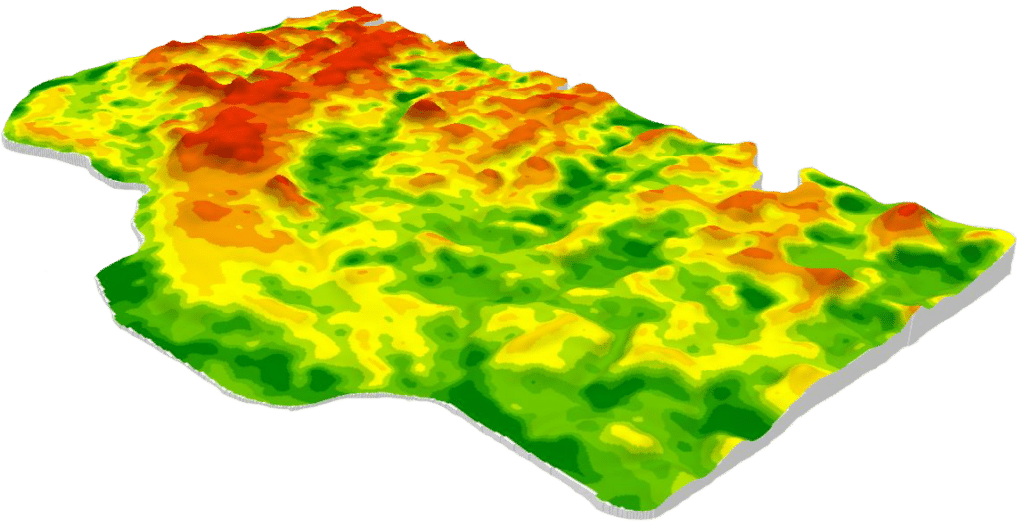

“People may not understand it at first, but as soon as they see the maps and we talk through the zones with them, they realize it’s a really well drawn-out map of their paddock,” said Correll. “It’s been interesting to think back in time of where that soil was moved over many decades and the elevation data ties it in perfectly. I’m finding some high EC on the mid-slopes and sometimes the depression is slightly lower, and then sure enough the pH is through the roof on the mid-slope rather than on the depression. Once you cover a lot of paddocks, you start to think ‘where would that water have moved’? You can tell a lot by the topography.”

A local service with experience in precision ag as well as agronomy is an asset to farming operations, and that is exactly the value that Peninsula Precision Ag can provide their clients. Additionally, Correll looks forward to exploring weed management through the use of SWAT CAM and finding more effective herbicides.

“In my partnership with SWAT MAPS, I’m excited to be creating highly detailed maps compared to the traditional grid sampling method. I’m able to further back up my data and find correlations with nutrient availability on calcareous soils,” said Correll. “My agronomy knowledge and experience with precision ag coupled with the premium products and service that SWAT MAPS offers allows me to help my customers make more informed and more profitable decisions.”

The SWAT MAPS team is excited to grow their network of service providers in Australia with the new addition of Peninsula Precision Ag. Please join us in welcoming Matt Correll by following him on Twitter @MattCorrell2.

Contact:

Matt Correll

0438651622

matt@peninsulaprecisionag.com.au